What Is Scaffolding?

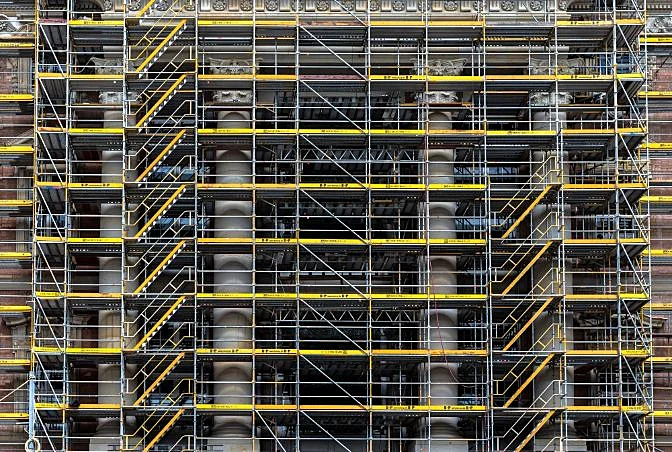

Scaffolding is essentially a temporary framework, usually made of metal poles and wooden planks, designed to support workers, inspectors, and maintenance personnel who need to work at heights. Whether it’s for construction, repairs, or cleaning tall buildings, scaffolding provides a stable platform for these tasks.

[Note: This article focuses on scaffolding in the context of industrial work. If you're looking to learn about scaffolding in education, check out this insightful article from Grand Canyon University.]

Believe it or not, the use of scaffolding dates back to the Stone Age! Archaeological evidence shows that early humans used scaffolding-like structures over 17,000 years ago to create the famous cave paintings at Lascaux. In ancient times, civilizations like Egypt and China also utilized basic scaffolds made of wood and tied together with ropes for construction purposes.

Fast forward to today, and scaffolding has evolved dramatically from its humble beginnings. Modern scaffolds come in various designs and materials, offering tailored solutions for different projects and industries.

This article will explore how scaffolding is used today, its various types and components, how to build it, and whether it’s better to rent or buy. We'll also examine how new drone technology is transforming the industry by reducing reliance on traditional scaffolding methods.

What Is Scaffolding?

A scaffold, also referred to as scaffolding or staging, is a temporary structure designed to give workers a stable platform for working at heights or accessing hard-to-reach areas. These structures are commonly used in building construction, maintenance, and repair of buildings, bridges, and other structures.

The Benefits of Scaffolding

Why has scaffolding been around for so long? Because it works! Even today, scaffolding remains one of the most effective ways to ensure safe and efficient work at heights.

Here are the key advantages of using scaffolds:

- Accessibility: Scaffolding allows workers unrestricted access to nearly any part of a structure.

- Balanced work: Workers can maintain their balance easily on scaffolds, enabling them to move freely while performing tasks.

- Easy assembly/disassembly: Scaffolding is relatively simple to set up and dismantle, making it convenient for various jobsites.

- Durability: Most scaffolds can withstand prolonged usage regardless of whether they're made from wood or steel.

- Safety: One major benefit of scaffolding is providing workers with a secure surface for their operations. However, eliminating human presence altogether during such tasks would be ideal—later in this guide, we'll discuss how drones can assist inspectors in minimizing exposure to risky situations.

- Bridging gaps: Certain construction activities require lengthy detours between specific points on-site, wasting valuable time. Scaffolding bridges can cut down on travel distances for employees.

The Risks Involved With Working On Scaffolding

Anytime someone needs to operate at elevated levels, there exists inherent risks involved—and temporary setups like scaffolding aren't exempt from these perils either.

According to OSHA (Occupational Safety And Health Administration), approximately 4,500 injuries and 60 fatalities occur annually due to incidents linked to scaffolding in America alone. Falls from scaffolding account for roughly 25% of all workplace deaths within this sector. Furthermore, nearly three-quarters of those injured cited defective planks or supports giving way, slipping, or being struck by falling objects as causes behind their accidents. Lack of proper fall protection training ranks among the top violations found on construction sites worldwide.

Despite its widespread use globally, the injury rate associated with scaffolding isn't excessively alarming; nonetheless, it does underscore the importance of prioritizing safety measures whenever possible.

Curious about what poses the greatest threats when operating on scaffolds?

Below are some common hazards:

- Defective Equipment: Faulty scaffolding often leads to accidents. Examples include compromised steel tubing or misaligned screws.

- Falling Objects: Tools, building materials, debris falling onto people below frequently results in injuries. A good practice involves covering each level of scaffolding to prevent such mishaps.

- Weather Conditions: Operating at height becomes perilous under adverse weather conditions like rain or snow making surfaces slippery while temperature changes might weaken connections causing planks to loosen up.

- Non-compliance With Standards: Overloading scaffolds near hazardous energy sources poses additional risks beyond typical ones mentioned earlier.

- Lack Of Proper Training: Both setting up and using scaffolding require specialized knowledge regarding safety protocols relevant specifically towards the kind being erected along with awareness about potential dangers linked therewith.

- Weak Planking Support Systems: All sorts of work demand robust plankings ensuring worker security against falls arising out of weakened supports posts mast climbers pump jacks etcetera alike mechanisms.

- Inexperience Negligence And Incompetence: Working alongside untrained inexperienced individuals lacking seriousness towards handling risks especially concerning scaffolding proves extremely hazardous indeed!

- Inadequate Safety Gear Supply: Even when scaffolds meet design manufacturing standards still provision of requisite protective gear remains indispensable.

- Poor Construction Practices: Improper assembly including failure attaching all connection points installing braces guardrails et cetera contributes heavily toward accidents occurring onsite regularly.

- Insufficient Maintenance: Regular upkeep ensures structural integrity remains intact over time preventing wear tear slipperiness amongst other potential hazards developing due neglectful care routines.

Applications Of Scaffolding

Today scaffolding serves numerous functions across diverse fields. Some of its most frequent applications include:

Cleaning: Cleaning staff often utilize scaffolding to wash windows and other exterior components of skyscrapers.

Construction: Essential for tall buildings like skyscrapers but equally important for ground-level constructions too.

Industrial Inspections: Visual examinations or non-destructive tests performed inside massive boilers pressure vessels externally require special arrangements facilitating access otherwise impossible without scaffolding assistance.

Maintenance: Initial inspections identify areas needing attention prompting maintenance teams to repair identified issues standing safely atop scaffolding platforms.

Other Uses: Different types of scaffolding find application in art installations concert stages exhibition stands grandstands observation towers shoring ski ramps et cetera.

Alternatives To Scaffolding Using Inspection Drones

We've already discussed drawbacks such as safety concerns involving falls dropped tools slow setup times et cetera plus alternatives available depending upon circumstances like rope access sometimes preferred over conventional scaffolding setups due flexibility targetted approach advantages.

For industrial inspections comprising visual surveys and non-destructive evaluations drones emerge as promising substitutes replacing traditional scaffolding requirements. Remote data collection through drones eliminates personal risk exposure allowing inspectors safer options.

Drones like Flyability's Elios 3 showcased above enable flying directly into high locations capturing high-resolution visuals permitting inspectors minimal interaction required physically reaching these spots thereby reducing dependence entirely upon scaffolding systems. Modular payloads accommodate varied sensor attachments catering specific project needs ranging from ultrasonic thickness gauges radiation dosimeters etcetera accordingly.

Some compelling reasons why inspectors favor drones over conventional internal scaffolding include:

- Safety: Since drones gather information remotely, personnel do not face direct exposure standing high above ground collecting critical details themselves.

- Economic Savings: Erecting dismantling temporal frameworks like scaffolds incurs substantial costs sometimes amounting tens hundreds thousands dollars depending scale involved. Utilization drones drastically cuts down these expenditures significantly benefiting enterprises financially.

- Reduced Operational Downtime: Given lengthy procedures associated with putting up taking down scaffolds delays ensue impacting operational timelines adding further financial burdens organizations endure. Employing drones negates necessity relying heavily on scaffolding thus enhancing profitability considerably.

- Increased Efficiency: Faster acquisition rates compared manual inspections conducted traditionally boosts overall productivity streamlining processes effectively.

tungsten carbide plate price, tungsten carbide wear plate, cemented carbide plate, carbide plate stock, carbide wear plates

Zigong Tianyi Industry Co., Ltd , https://www.tyalloypins.com