As the semiconductor industry advances, the complexity of connections between chips continues to grow. Traditional printed circuit board (PCB) technologies face significant challenges when dealing with higher frequency and speed requirements. Ensuring stable and reliable interconnections between high-speed and high-density chips has become essential.

Additionally, the rising power consumption of chips has led to increased heat generation, which requires an efficient cooling system to keep chips operating optimally.

As a result, the interposer PCB—a new type of PCB—has emerged.

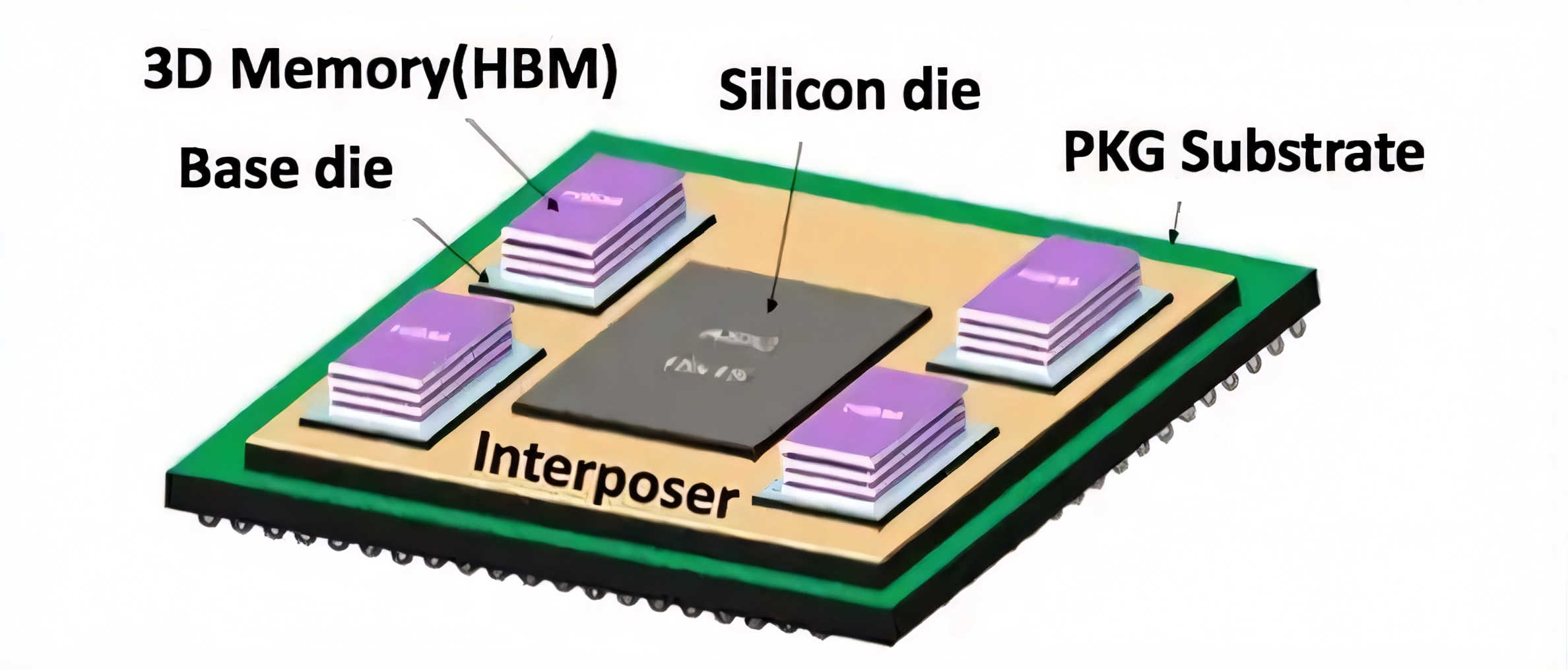

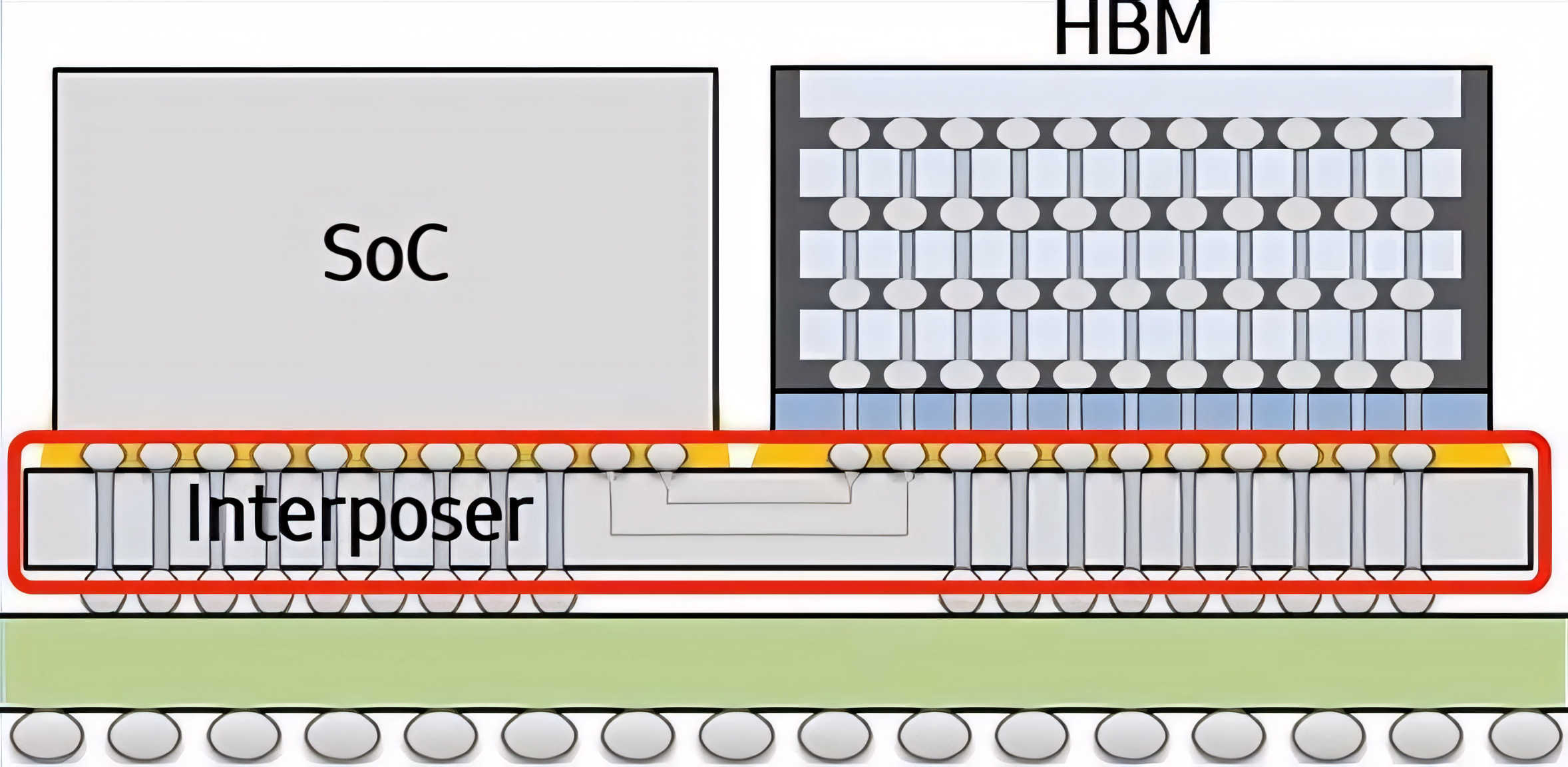

The term "interposer PCB" refers to a highly precise, high-layer arbitrary interconnection high-density interconnect (HDI) PCB. It plays a crucial role in connecting and integrating various electronic components, acting as an intermediary layer for chip connections. It achieves electrical connections through pad leads and interconnects with the chip's micro bumps (uBump) and routing in the intermediary layer. The intermediary layer uses through-silicon vias (TSV) to connect upper and lower layers.

This PCB's design features inner layers connected to outer layers via laser microvias and dense routing, creating a multi-structured board with BGA connections on the top side and pad connections on the bottom side.

Interposer PCBs hold immense value and importance in enhancing the performance of integrated circuits in various ways.

Firstly, interposer PCBs offer higher connection speeds and reliability for semiconductor products. Made from high-performance materials, interposer PCBs enable short-distance, high-density connections between integrated circuits, significantly boosting chip data transmission rates.

Secondly, interposer PCB technology tackles signal integrity and power consumption issues. By using interposer technology, signal pins can be directly connected to the interposer layer, reducing the length of signal transmission paths, thus minimizing signal loss and improving signal integrity.

Thirdly, the interposer layer also contributes to thermal management, effectively lowering chip temperatures.

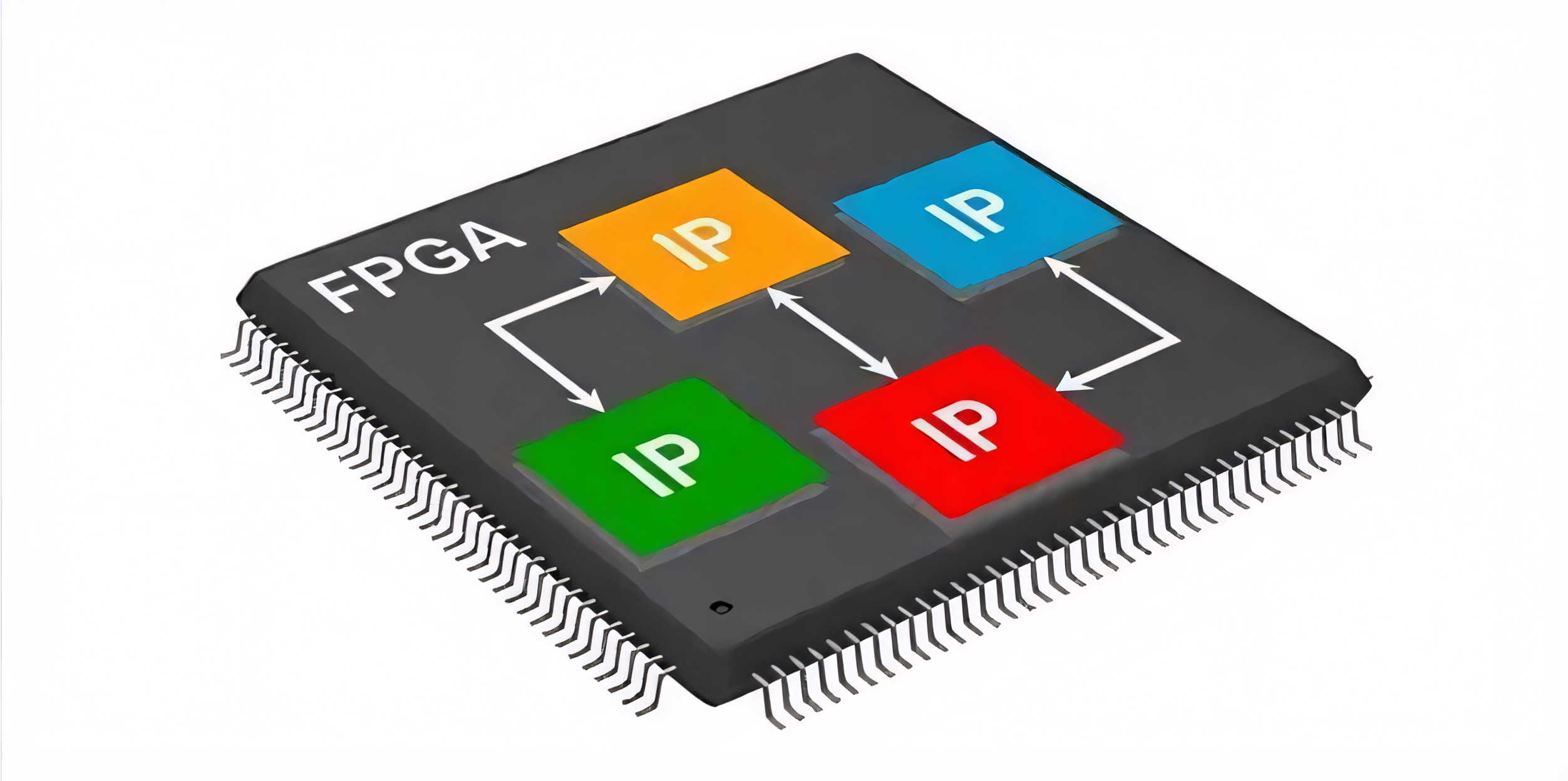

Lastly, interposer PCB technology facilitates the connection of heterogeneous integrated circuits. By placing integrated circuits with different functionalities on the same interposer layer, it allows for interconnections between various chips, thereby enhancing the overall performance and efficiency of semiconductor products.

In summary, interposer PCBs are widely utilized in high-performance computing, artificial intelligence, data centers, and communications. In high-performance computing systems, interposer technology can connect multiple processing chips, enabling larger-scale computational capabilities. In the field of artificial intelligence, interposer technology supports interconnections between different chips, improving the training and inference speeds of neural networks. For data center and communication applications, interposer technology provides higher transmission rates and bandwidth to meet the demands of big data processing and high-speed communication.

As a leading manufacturer of high-end HDI PCBs, PCBWay stays ahead of market trends. In response to the urgent demand from clients for high-order arbitrary interconnection (Anylayer) HDI boards, our product research institute has been working hard to overcome technical hurdles, ultimately successfully developing high-layer, high-order arbitrary interconnection interposer PCBs.

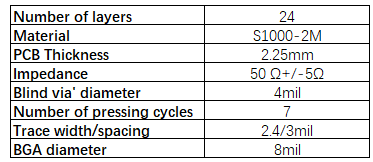

Here, we will showcase the details of this high-precision circuit product using the 24-layer, 6-order Anylayer HDI PCB as an example.

1. Product Parameters

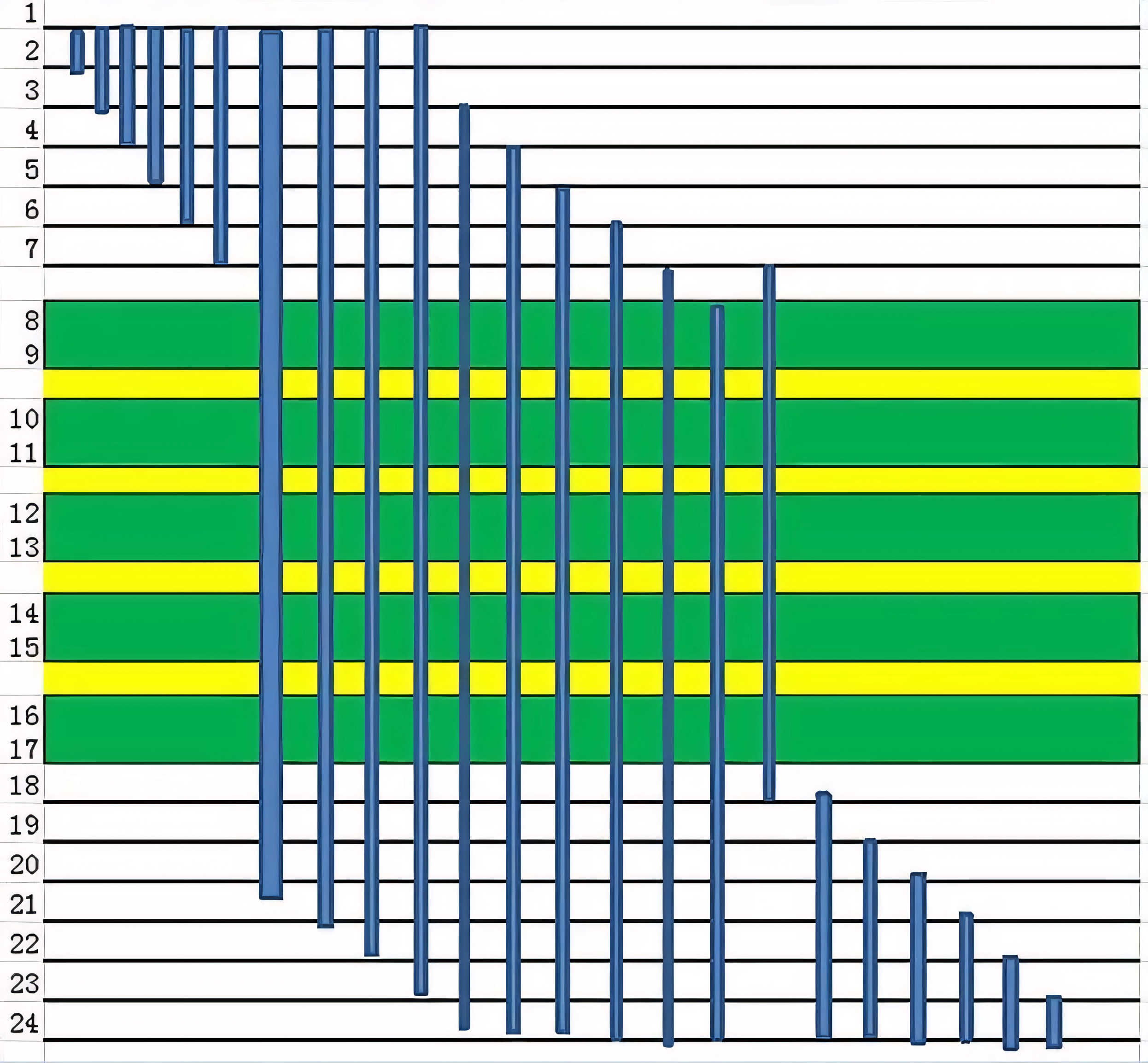

2. Product Structure

3. Technical Challenges

Challenge 1: The buried via PCB thickness from L7 to L18 is 1.0 mm, with a mechanical through-hole diameter of 0.1 mm, resulting in a hole aspect ratio of 10:1, making mechanical drilling difficult.

Challenge 2: The BGA pitch is 0.35 mm, and the distance from the hole to the conductor trace is 0.13 mm, which makes it easy for misalignment during multiple laminations.

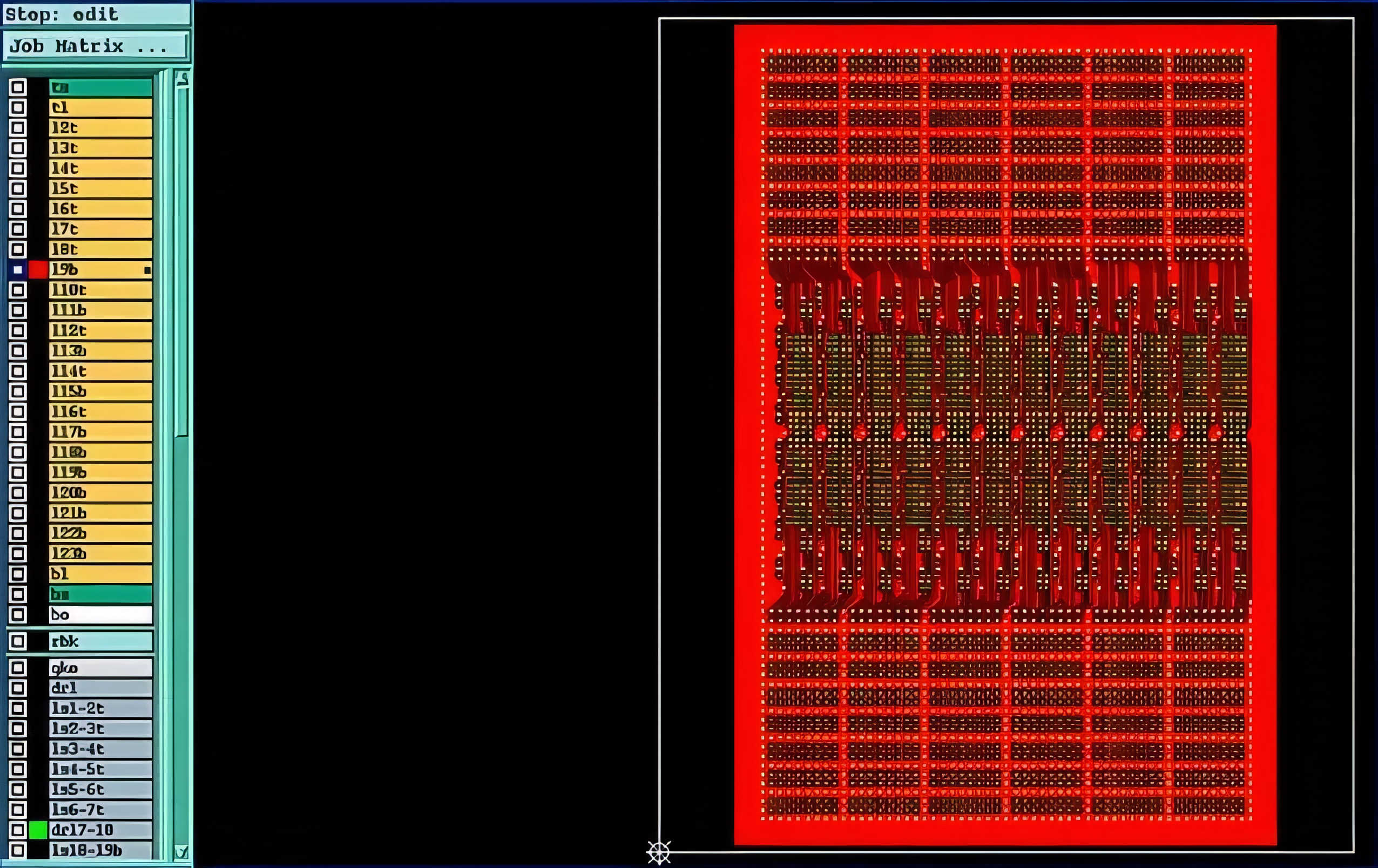

Challenge 3: The trace width/spacing is 2.4/3 mil, featuring dense routing. Below are some routing diagrams.

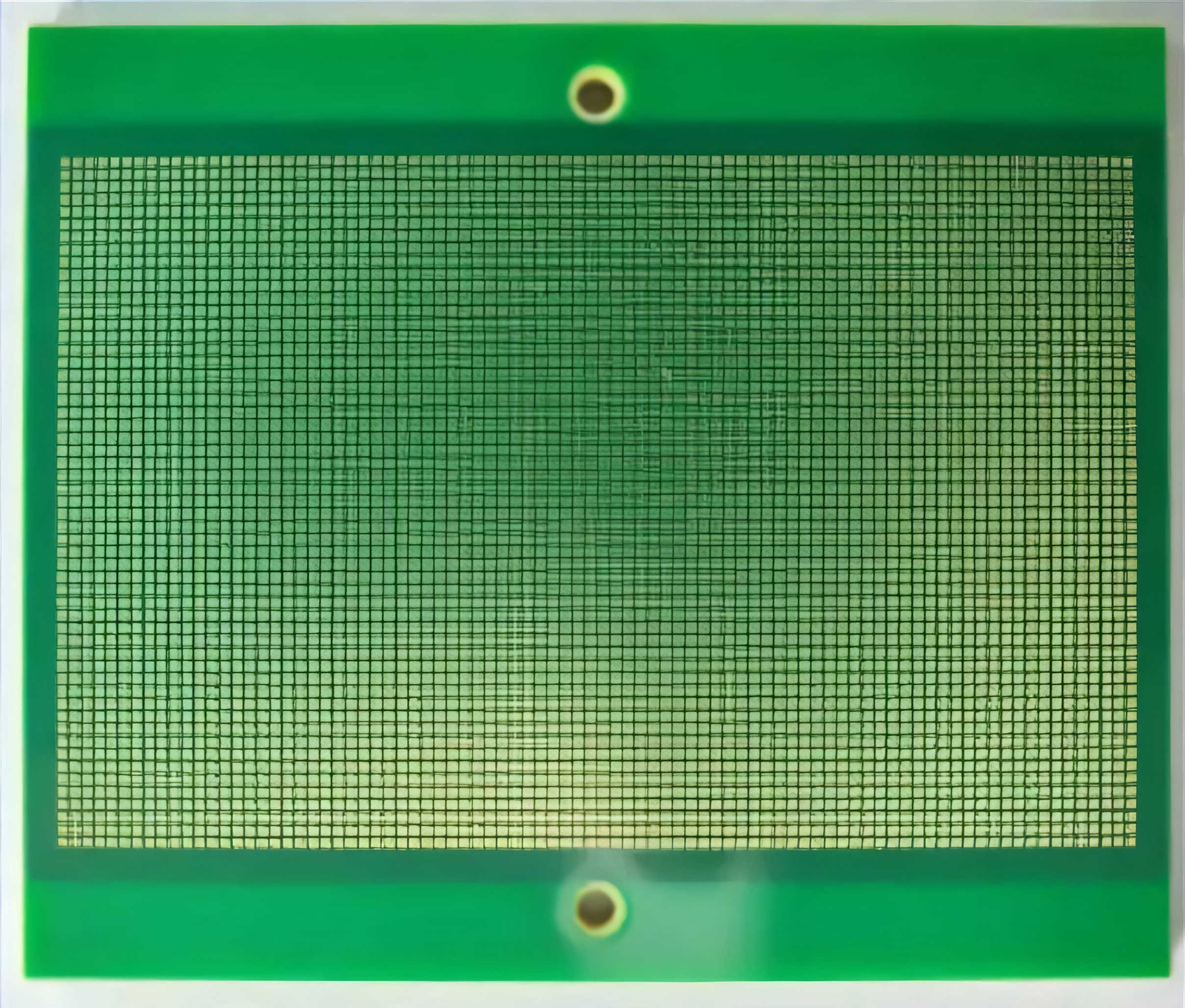

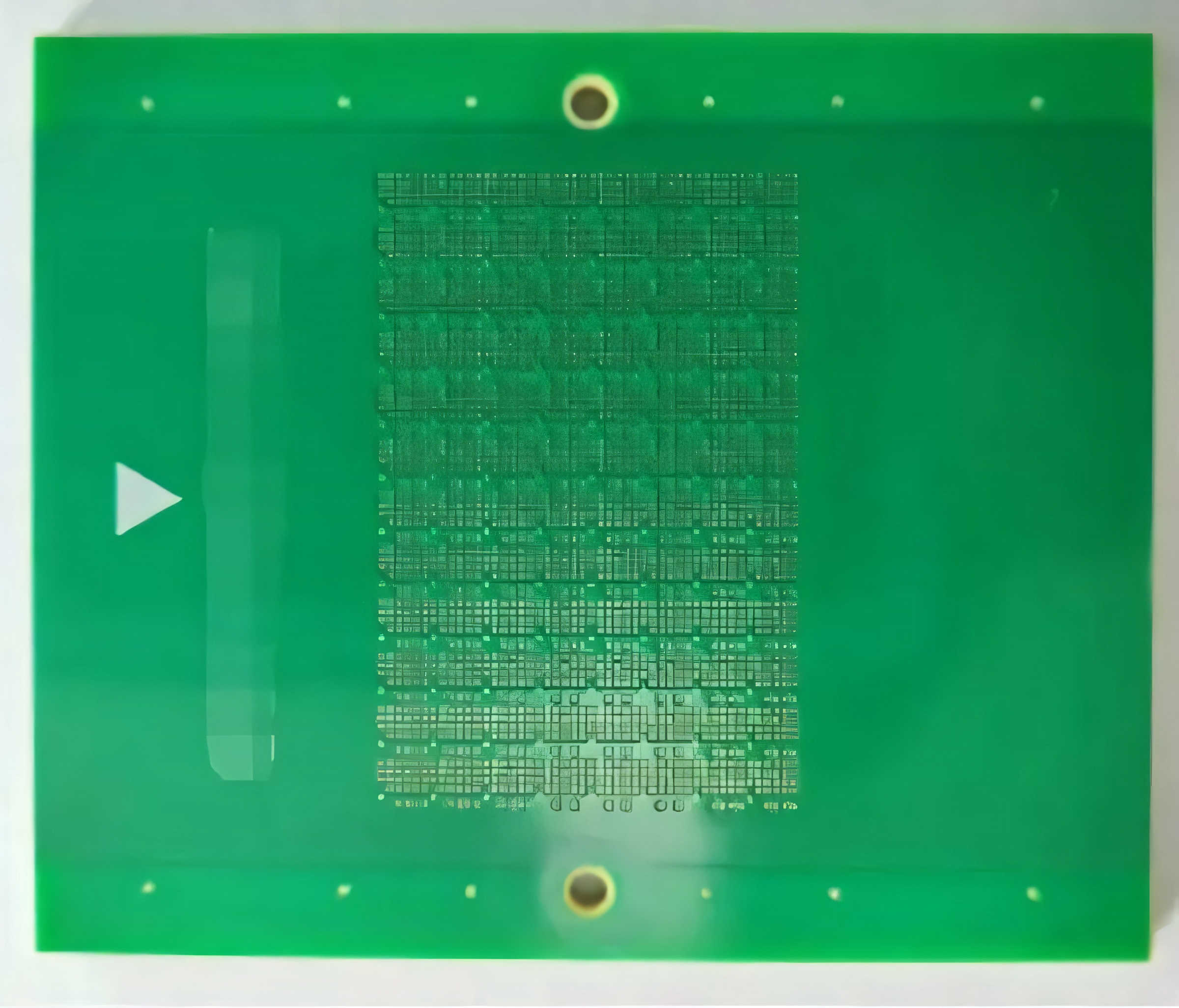

4. Finished Product Pictures

Plastic Tray With Characters,Flat Character Tray, Character Plastic Pallet, Character Plastic Pallet For Logistics

Jiangsu Ru Shun plastic industry Co., LTD , https://www.rushunsuye.com