When it comes to manufacturing metal parts and components, there are several methods available. Two of the most common ones are sheet metal stamping and metal fabrication. While these terms are often used interchangeably, they actually refer to different processes with unique benefits and applications.

When it comes to manufacturing metal parts and components, there are several methods available. Two of the most common ones are sheet metal stamping and metal fabrication. While these terms are often used interchangeably, they actually refer to different processes with unique benefits and applications.

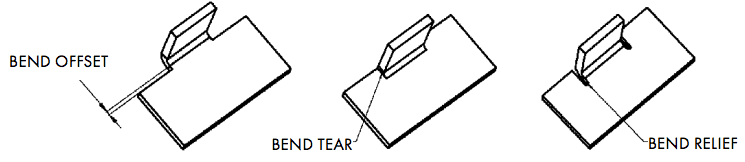

Sheet metal stamping is a specific type of metal fabrication that involves using dies and punches to shape metal sheets into desired forms. This process is ideal for high-volume production runs due to its efficiency and cost-effectiveness. On the other hand, metal fabrication is a broader term that includes various techniques like cutting, bending, and welding. It’s more flexible but typically requires more labor and time.

What is Sheet Metal Stamping?

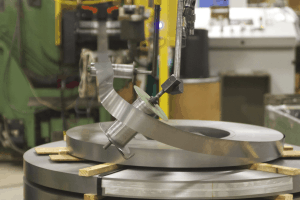

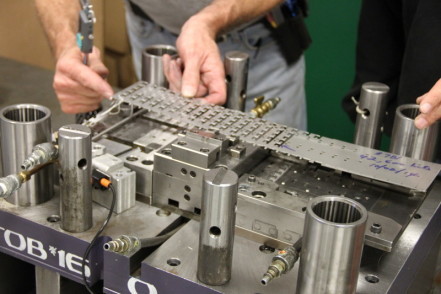

Sheet metal stamping is a manufacturing process where metal sheets are shaped using specialized tools such as dies and punches. It can be done in a single stage or through a multi-step progressive die process. In progressive stamping, a strip of metal is fed through a series of stations, each performing a different operation until the final part is completed. This method is highly efficient and ideal for mass production.

Some advantages of sheet metal stamping include:

- Lower per-unit cost for large quantities

- Ability to create complex designs

- High level of consistency and repeatability

- Compatibility with secondary operations

However, it does require significant upfront investment in tooling and setup. For smaller production runs or custom parts, other methods may be more suitable.

What is Metal Fabrication?

Metal fabrication refers to the process of shaping raw metal materials into finished products. This can involve cutting, bending, welding, and assembling metal pieces. Unlike stamping, which is often automated, fabrication is typically more hands-on and allows for greater customization. It’s well-suited for one-off projects or small batches where flexibility is key.

Key benefits of metal fabrication include:

- Fast prototyping capabilities

- Wide range of techniques (e.g., laser cutting, shearing)

- Customization options

- Easy design modifications

While metal fabrication offers flexibility, it can be more expensive for large-scale production. It also tends to have longer lead times compared to stamping. However, for unique or low-volume parts, it remains an excellent choice.

Quality Metal Stamping Services from Engineering Specialties, Inc.

If you're looking for reliable sheet metal stamping services, Engineering Specialties, Inc. (ESI) is here to help. With over 30 years of experience, we provide top-quality manufacturing solutions using advanced automation and expert craftsmanship. Our team focuses on every detail of your project, from initial design to final delivery.

Our state-of-the-art facilities and trained professionals ensure precision, quality, and efficiency in every product we deliver. We offer everything from small batch runs to large-scale production, all while maintaining strict quality control standards. With Six Sigma Black Belt-trained QA personnel on staff, we guarantee consistent performance across all our services.

Ready to get started on your next project? Contact us today to request a quote and discover how ESI can meet your metal stamping needs.

Disc Spreader,Jbs Spreaders,Fertilizer Buggy Spreader,Bunning Disc Spreader

Gongzhuling Huaxi Agricultural Machinery Manufacturing Co.LTD , https://www.hxzbjx.com

Comments are closed