Major Cement Company Enhances Stockpile Measurement with Elios 3

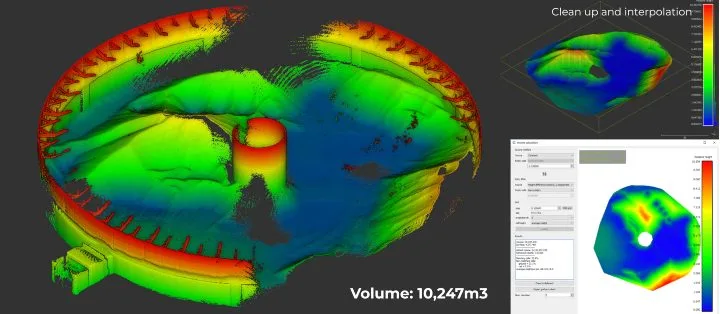

A French cement plant implemented LiDAR technology from the Elios 3 to measure clinker stockpiles, significantly improving both safety and precision in the inventory process.

Key Benefits at a Glance

|

Efficiency In just half an hour—10 minutes for collecting data and another 20 minutes for processing with GeoSLAM Connect—the plant staff generated an accurate measurement of the clinker stockpile. |

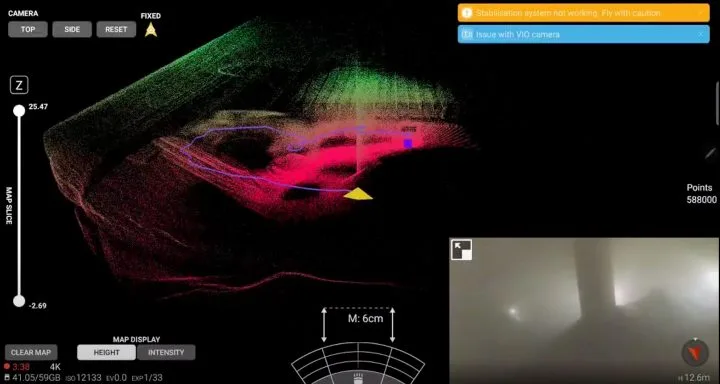

Operation in Hazy Conditions Despite the high dust levels inside the silo reducing visibility, the Elios 3's 3D Live Map enabled pilots to navigate smoothly and complete the task without issue. |

Enhanced Safety By eliminating the need for workers to climb onto platforms high above the ground, the Elios 3 drastically reduced risks associated with manual stockpile measurements. |

Introduction

Clinker, a key ingredient in cement production, is often stored in large silos before being processed into the final product. Accurately measuring the quantity of clinker is essential for effective production planning.

Traditionally, plant workers would manually estimate clinker quantities by standing on elevated platforms and probing the material with poles. This method was not only time-consuming but also fraught with inaccuracies and safety hazards.

Customer Challenges

Working inside clinker silos presents unique challenges. High dust concentrations, low light conditions, and the risk of falling from heights made conventional measurement techniques particularly hazardous.

At this specific plant, employees faced additional risks as they had to balance on unstable platforms positioned 25 meters (82 feet) above the ground. The imprecise nature of these estimates left room for error in production forecasts.

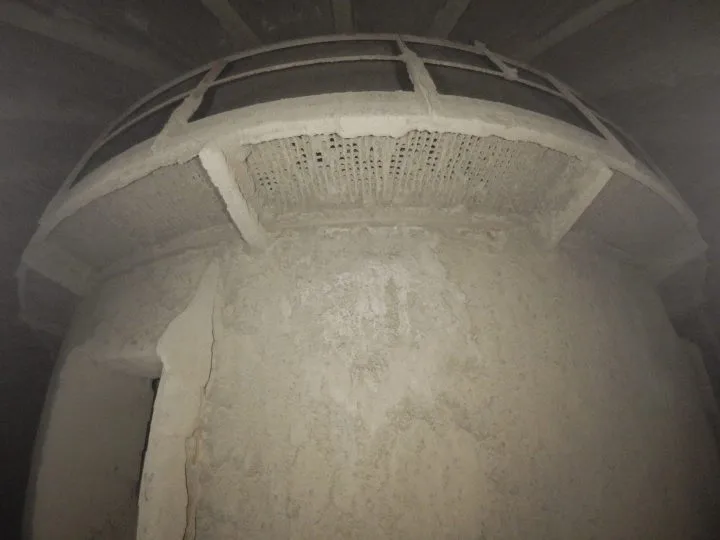

The precarious platform where inventory data was collected

Realizing the limitations of current methods, plant administrators sought a better way to conduct stockpile measurements.

Adopting the Solution

After evaluating various options, the plant decided to trial the Elios 3 drone equipped with LiDAR sensors. The device promised to deliver precise data even under challenging conditions.

During testing, operators discovered that the Elios 3 could create detailed 3D maps in real-time through its SLAM technology. This capability proved invaluable when navigating the murky interiors of the silo.

A comparison between the drone’s live feed and its 3D map

With its advanced features, the Elios 3 allowed operators to maintain situational awareness regardless of visibility levels, ensuring safe and efficient operations.

Outcomes

The initial test run exceeded expectations. Not only did the Elios 3 provide faster results compared to previous manual processes, but the accuracy of the stockpile measurements was far superior.

Operators noted that the drone handled itself admirably amidst the dense dust clouds thanks to its sophisticated stabilization systems. Furthermore, the entire operation required minimal human intervention, thus minimizing exposure to potential accidents.

Some key advantages highlighted during this project include:

- Rapid Execution: From takeoff to finished analysis, the whole procedure took less than thirty minutes.

- Precision: Measurements taken via the Elios 3 surpassed those obtained manually by a significant margin.

- Operability in Haze: Thanks to its innovative mapping tools, the Elios 3 performed flawlessly even when visibility dropped sharply.

- Security: Eliminating the necessity for risky climbs ensured worker protection throughout the exercise.

- Comprehensive Coverage: Full coverage of the clinker stockpile was achieved effortlessly.

The Elios 3’s 3D map guided pilots safely through dusty environments

Secondary Applications

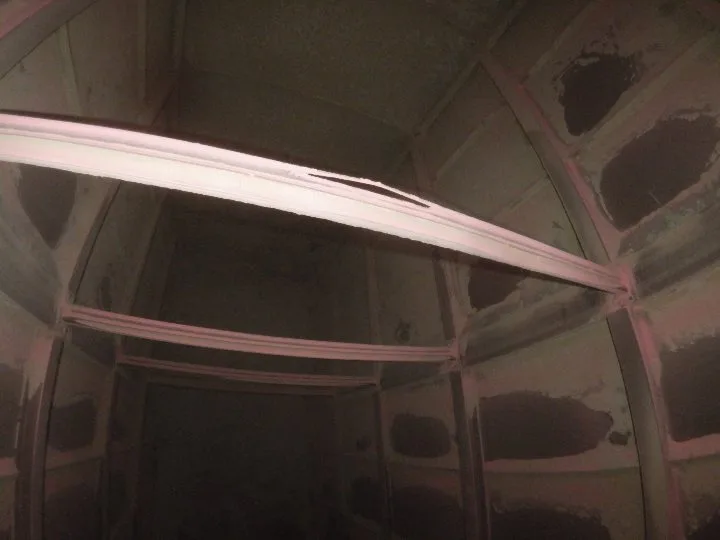

Beyond stockpile management, the Elios 3 was also deployed to inspect a critical filter shaft. Initial observations suggested possible structural damage to some internal supports.

Upon closer examination facilitated by the drone’s camera feed, technicians confirmed substantial corrosion on multiple beams. Armed with this knowledge, maintenance teams promptly scheduled necessary repairs to prevent operational disruptions.

Damaged support beams detected inside the filter shaft

Final Thoughts

The successful implementation of the Elios 3 has prompted the plant to consider integrating this solution into their routine inventory practices permanently. Beyond stockpile assessments, there is growing interest in leveraging the drone for periodic inspections across several critical facilities.

Its ability to function effectively in dusty surroundings opens up numerous possibilities for enhancing maintenance routines while safeguarding personnel health and safety.

Introduction to GENT ordinary pool heater heat pump

Applicable scenarios

1. Pool type: indoor/outdoor pool, spa pool, children's paddling pool, etc.

2. Climate conditions: The applicable ambient temperature range of this ordinary heat pump pool heater is -15~43℃, so it is mainly suitable for temperate and subtropical regions.

3. Scale requirements: This pool heaters for above ground pools can be used to meet the heating needs of users for swimming pools of all sizes, from home use (small villa swimming pool) to commercial use (hotel, gymnasium large swimming pool).

Unit Purpose

This above ground heat pump for pool is a single heat type heat pump product with air as heat source, which can only achieve the purpose of heating swimming pool water.

Installation and maintenance

1. Installation points

â‘ Choose a well-ventilated, unobstructed outdoor location

â‘¡ Ensure that the water circulation system matches (water pump flow, pipe insulation)

â‘¢ Reserve space for equipment maintenance

2. Maintenance recommendations

â‘ Clean the evaporator fins of the thermo pump pool heater regularly (to prevent dust from clogging)

â‘¡ Winter drainage antifreeze (not in all-weather operation environment)

â‘¢ Check the condensing pressure and circuit system every two years

Data required for model selection

If users need specific selection recommendations or energy efficiency calculations, you will need to provide information such as the pool size (length × width × depth), regional climate, frequency of use, whether the pool is indoors or outdoors, whether there is Air Conditioning around the pool, etc., so that we can determine the most suitable model of the electric heat pump pool heaters for inground pools and data for you and specify the most suitable pool heating solution for you.

Pool Heaters For Above Ground Pools,Heat Pump Pool Heater,Above Ground Heat Pump For Pool,Thermo Pump Pool Heater,Electric Heat Pump Pool Heaters For Inground Pools

GUANGZHOU GENT NEW ENERGY TECHNOLOGY CO., LTD , https://www.gentgz.com