# Understanding ATTI Mode: A Comprehensive Guide

ATTI mode, or Attitude Mode, is often considered the most hands-on approach to drone piloting. As drone technology continues to evolve, the focus has increasingly shifted toward automation, reducing the workload for pilots. Features like advanced sensors and smart flight modes have made drone operation simpler than ever.

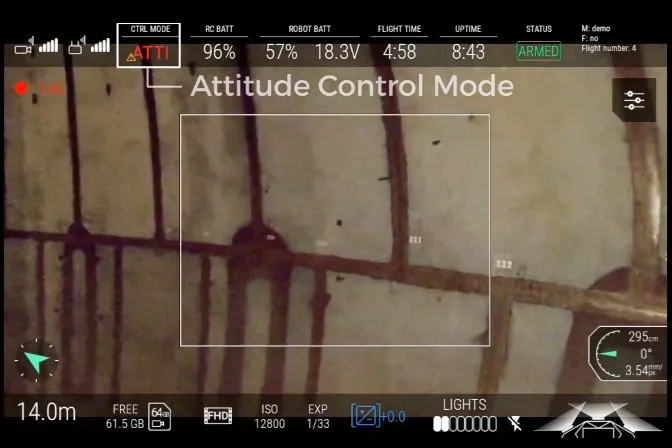

However, there are certain scenarios where ATTI mode becomes indispensable. One such instance is conducting indoor inspections where GPS signals are unreliable. In ATTI mode, the drone relies solely on the pilot's input to manage its orientation, with optical sensors temporarily disabled. Pilots often activate ATTI mode when they encounter stability issues or unpredictable behavior due to limitations in optical sensor capabilities.

*Figure: No GPS Zone*

## What Exactly Is ATTI Mode?

In ATTI mode, the drone operates without the aid of intelligent flight features such as GPS positioning or optical sensors. This means the drone is fully controlled manually by the pilot, without any automatic corrections or assistance. Most drone operators are familiar with flying in either GPS or OPTI mode, but ATTI requires the pilot to take full responsibility for maintaining the drone's balance and direction.

For those who prefer to rely on drone automation, mastering ATTI mode might seem daunting. However, understanding how to fly in this mode can be invaluable, particularly in situations where the drone needs to operate independently of GPS signals.

## When Should You Use ATTI Mode?

ATTI mode isn’t as prevalent today as it was in earlier models. Early drones allowed users to toggle into attitude mode, but with advancements in indoor drone technology, this capability has become essential. Drones cannot connect to satellites indoors, making ATTI mode crucial for such operations.

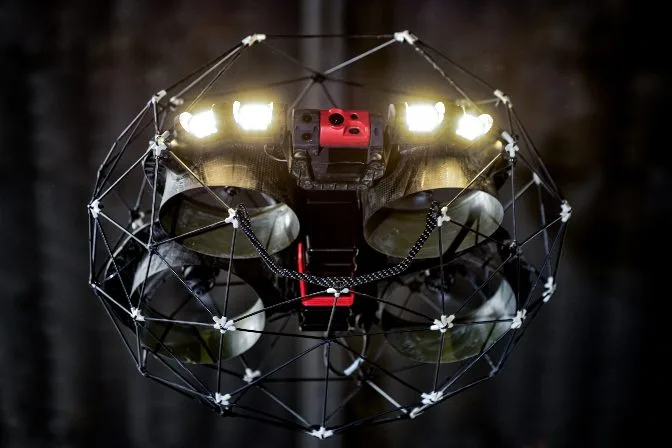

Take, for example, the mining sector. Mining environments are fraught with danger and unpredictability, prompting the industry to adopt drone technology early on. Specialized drones like the Elios 3 are designed specifically to operate in GPS-denied environments, utilizing ATTI mode to navigate effectively.

*Figure: The Elios 3*

## Practical Applications of ATTI Mode

ATTI mode proves beneficial in scenarios where GPS signals are compromised:

- **Indoor Inspections**: Drones are frequently used to inspect boilers, sewers, tanks, mines, and other confined spaces where GPS signals are unavailable.

- **Bridge Inspections**: Metal beams can significantly disrupt GPS accuracy, making ATTI mode necessary.

- **Building Inspections**: Concrete and steel structures often interfere with GPS signals, necessitating ATTI mode for precise navigation.

- **Critical Infrastructure**: Government facilities, such as military bases, often restrict GPS usage for security purposes.

The Elios 3 is a prime example of a drone optimized for demanding environments, where precision and accuracy are paramount.

## How Does ATTI Mode Operate?

Flying in ATTI mode places full control of the aircraft in the pilot's hands. Without GPS or vision positioning systems, this mode demands manual control. Drones using ATTI rely on onboard barometers, which measure air pressure to estimate altitude, helping to maintain level flight. However, without GPS, the drone may drift in different directions if influenced by external forces like wind.

### What Triggers ATTI Mode Automatically?

Several conditions can prompt the drone to enter ATTI mode:

- Flying over reflective or monochromatic surfaces

- Operating a drone with dirty vision sensors

- Flying near large concrete or metallic structures

- Using high-speed flight modes, which can disrupt signal acquisition

## Advantages of Flying in ATTI Mode

While ATTI mode is primarily a fallback when GPS is unavailable, there are distinct benefits to using it:

1. **Preparation for the Unexpected**: GPS loss or signal interference can lead to unforeseen complications. Familiarity with ATTI mode prepares pilots for such situations.

2. **Optimized for Indoor Operations**: Indoor flights present unique challenges due to obstacles and signal disruptions. ATTI mode, relying on barometric sensors and a skilled pilot, is ideal for these conditions.

3. **Smooth Footage**: While regular flight modes offer stability, ATTI mode provides smoother footage by eliminating frequent position adjustments, resulting in cleaner video recordings.

## Tips for Flying in ATTI Mode

Mastering ATTI mode requires patience and practice. Here are some tips to get started:

### 1. Begin Gradually

Approach ATTI mode as if you’re flying for the first time. Avoid rushing through maneuvers. Start with basic tasks like taking off, hovering, and landing. Try flying in a figure-eight pattern or practicing roll, pitch, and yaw movements.

### 2. Practice in Open Spaces

Always practice in spacious areas without people or water bodies nearby. Keep the drone within a manageable range to ensure you can visually assess its position. Utilize the live video feed to enhance situational awareness.

### 3. Monitor Weather Conditions

ATTI mode lacks GPS safeguards against wind drift. Be mindful of weather conditions, especially strong winds, which can challenge your control over the drone.

### 4. Use an Affordable Drone for Practice

Avoid damaging expensive drones while learning. Cheaper models without GPS can simulate ATTI conditions, offering a safer learning environment.

## The Future of ATTI Mode

Although most consumer drones are moving away from manual modes, ATTI mode remains relevant in specialized fields. As industries adopt drones for niche tasks, more drones like the Elios 3 will emerge, catering to these specific needs.

## Other Drone Flight Modes

Besides ATTI, there are several other flight modes:

### ASSIST Mode

ASSIST mode uses sensors to maintain stability by measuring distance and motion relative to nearby objects. While effective, its accuracy diminishes under poor lighting or dusty conditions.

### GPS Mode

GPS drones utilize satellite networks for precise positioning. Features like waypoint navigation and return-to-home rely heavily on GPS signals.

### OPTI Mode

OPTI mode uses optical sensors for stabilization without GPS. It’s more stable than ATTI for indoor use but still lacks full manual control.

In conclusion, mastering ATTI mode is essential for drone pilots looking to excel in diverse environments. Practicing regularly ensures readiness for any situation.

The Plastic Crushing Machine, also known as a plastic granulator or Plastic Shredder, is an industrial device designed to reduce plastic waste into smaller, manageable pieces.

1. Single Shaft Shredder

This type of machine features a single rotating shaft with cutting blades. It is suitable for processing larger, tougher plastic materials like thick-walled pipes, blocks, and pallets. The output particle size can be controlled by the screen mesh size, which typically ranges from 20-26mm for hard materials.

The single shaft shredder provides efficient size reduction and is designed for high output. It is equipped with a high-torque motor to drive the blades, ensuring the necessary force to crush even the toughest plastics.

Application Scenarios: Widely used in plastic recycling plants and manufacturing industries for processing post-consumer and post-industrial plastic waste.

2. Double Shaft Shredder

Equipped with two intermeshing rotating shafts with blades, this machine is designed for heavy-duty applications. It can handle mixed and contaminated plastic waste, offering higher throughput and greater flexibility in processing different types of plastics. The screen mesh size for film materials is usually between 40-50mm.

The double shaft shredder provides powerful crushing capabilities and is suitable for large-scale production scenarios. It features a robust construction and is designed for continuous operation.

Ideal for municipal waste management and plastic product manufacturers, where it helps in processing a wide range of plastic materials.

3. Granulators

Specifically designed for finer grinding and producing uniform granules, granulators are often used in the final stages of the recycling process. They are available in various sizes and capacities to suit different production needs. The machine's inner chamber width can range from 80 to 150 cm, and the motor speed can be adjusted within the range of 400 to 800 RPM.

Granulators produce high-quality recycled plastic granules, which can be reused to manufacture new products. They are equipped with advanced control systems for automated operation, enhancing efficiency and safety.

Used in plastic recycling plants and manufacturing industries for producing high-quality recycled plastic materials. They are also suitable for reprocessing defective products or production waste.

4. Jaw Crushers

Ideal for large, bulky plastic items, jaw crushers use a compressive force to break down the material. They are designed to handle large volumes of plastic waste and reduce them to smaller, more manageable pieces.

Jaw crushers are known for their high crushing force and strong cutting ability. They are equipped with durable blades and a robust frame to withstand the mechanical stresses of crushing operations.

Application Scenarios: Widely used in the recycling and reutilization of waste plastic, jaw crushers help in reducing the volume of plastic waste, making it easier to handle and transport.

Plastic Crusher,plastic crushing machine

Zhangjiagang Polestar Machinery Co.,Ltd , https://www.polestarpm.com