The Difference Between Oxyfuel Cutting and Plasma Cutting and Choosing the Right One for Your Application

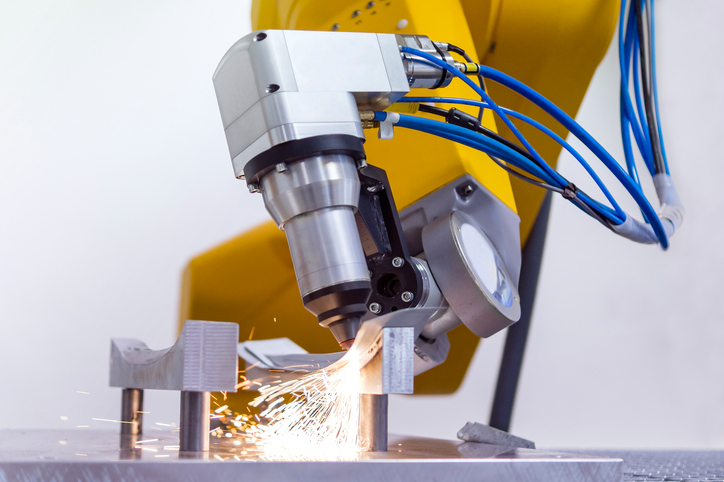

When it comes to automation in manufacturing, robotic cutting is a common and efficient solution. However, choosing between oxyfuel cutting and plasma cutting can be challenging. Both methods have their own strengths and limitations, making them suitable for different applications.

Understanding the differences between these two techniques is crucial for selecting the right one for your specific needs. Whether you're working with metals like steel or aluminum, the decision will affect the speed, precision, and overall efficiency of your production process.

The Basics of Plasma Cutting and Oxyfuel Cutting

Plasma cutting uses an electric arc to ionize a gas, typically compressed air, creating a high-temperature plasma jet. This jet is then directed through a nozzle to cut through conductive materials. The process is fast and ideal for thin metals, such as aluminum and stainless steel.

Oxyfuel cutting, on the other hand, relies on a combination of oxygen and fuel gas to heat the material to its ignition temperature. Once the metal is hot enough, a high-pressure oxygen stream is used to oxidize and remove the molten material, effectively cutting through the workpiece. This method is particularly effective for thick, ferrous metals like carbon steel.

The Advantages and Disadvantages of Plasma Cutting and Oxyfuel Cutting

Plasma cutting offers excellent speed and precision, especially for thinner materials. It's widely used in industries that require fast, clean cuts. However, it's less effective for thick metals and cannot be used on non-conductive materials.

Oxyfuel cutting excels when dealing with thick, iron-based materials. It provides a strong, clean cut and is often preferred for heavy-duty applications. But it’s slower compared to plasma cutting and not ideal for thin or non-ferrous metals.

Both technologies have their place in modern manufacturing. While plasma cutting is faster and more versatile for certain materials, oxyfuel cutting remains a reliable option for thick, ferrous metals. The choice ultimately depends on factors like material type, thickness, and desired cut quality.

Choosing between oxyfuel and plasma cutting isn’t always straightforward. By understanding the underlying technology and application requirements, you can make an informed decision that maximizes efficiency and performance in your production line.

For more insights into how Genesis Systems Group can help you choose the best cutting solution, explore our range of advanced robotic oxyfuel and plasma cutting systems designed for industrial excellence.

Posted in Robotic ApplicationsPipeline Heat Shrinkable Sleeve

Heat-shrinkable Sleeve In Pipeline,Pipeline Heat Shrink Sleeves,Pipeline Shrink Sleeves,Pipe Heat Shrink Sleeve

JINING XUNDA PIPE COATING MATERIALS CO.,LTD , https://www.xundapipelinetape.com