Understanding the Difference Between Oxyfuel Cutting and Plasma Cutting and How to Choose the Right One for Your Needs

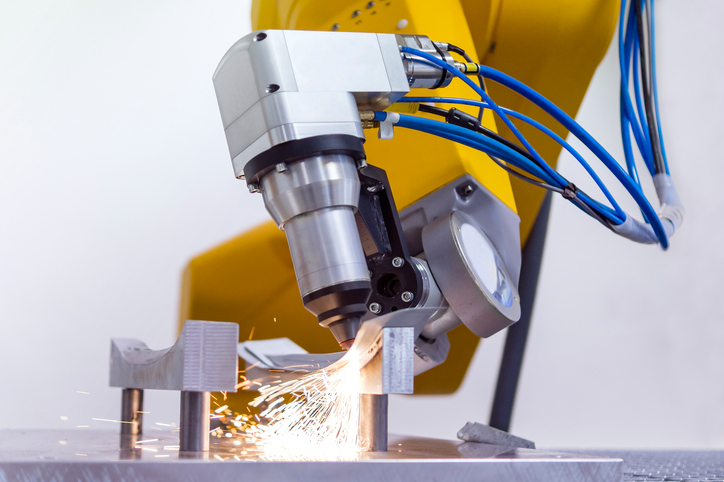

When it comes to automation in industrial production, robotic cutting is a common and efficient solution. However, choosing between robotic oxyfuel cutting and robotic plasma cutting can be a challenge. Both methods have their own strengths and weaknesses, and the right choice depends on your specific application needs.

Understanding the differences between these two technologies is essential for making an informed decision. Whether you're working with thick steel plates or thin aluminum sheets, each cutting method offers unique benefits that may suit your project better than the other.

The Fundamentals of Plasma Cutting and Oxyfuel Cutting

Plasma cutting works by passing an electric current through a gas (such as compressed air), which ionizes it into a high-temperature plasma. This plasma is then forced through a nozzle at high speed, creating a concentrated arc that melts and cuts through the material. The process is fast, clean, and ideal for non-ferrous metals like aluminum and copper.

Oxyfuel cutting, on the other hand, uses a combination of oxygen and fuel gas (like acetylene or propane) to heat the metal to its ignition temperature. Once the material is hot enough, a high-pressure oxygen jet is directed onto the cut, causing a chemical reaction that burns through the metal. This method is especially effective for thick ferrous materials such as steel.

Pros and Cons of Each Cutting Method

Plasma cutting is known for its speed and precision, making it a popular choice for thin metal applications. It’s also relatively easy to automate and can handle a wide range of materials. However, it's not as effective for very thick or ferrous metals, and the quality of the cut may not be as clean as with oxyfuel in certain cases.

Oxyfuel cutting excels when dealing with thick steel and provides a smooth, consistent cut. It’s also more cost-effective for large-scale operations. But it tends to be slower compared to plasma cutting, and it’s less suitable for thin materials due to the risk of warping or burning through.

Choosing between oxyfuel and plasma cutting often comes down to the type of material you’re working with, the thickness of the metal, and the desired cut quality. While both methods can be automated, they serve different purposes and are better suited for different applications.

If you're unsure which option is best for your project, consider consulting with an expert who can evaluate your specific requirements. Whether you need high-speed cutting or precision on thick metals, there's a solution that will meet your needs efficiently and effectively.

For more details on how Genesis Systems Group can help you choose the right cutting technology for your operation, visit our website today.

Posted in Robotic ApplicationsPipe Corrosion Protection Tape

Steel pipeline anti-corrosion layer is an important measure to control pipeline corrosion and ensure the service life of the pipeline, and the choice of anti-corrosion layer material is extremely critical.

The application of steel pipeline external anti-corrosion layer materials and technological development, based on the feasibility of advanced technology, economic rationality and convenient construction, combined with the working conditions of the pipeline and the natural geographical environment along the pipeline, so as to select the appropriate pipeline laying environment of the external anti-corrosion layer, to ensure the safe and stable operation of the pipeline in the service life of the period.

Marine Anticorrosion Pipeline Tape,Corrosion Protective Adhesive Tape,Corrosion Protection Tape,Machine Protection Adhesive Tape

JINING XUNDA PIPE COATING MATERIALS CO.,LTD , https://www.xundapipelinetape.com