Excavators are essential tools used across a wide range of industries. Whether it's breaking ground or moving earth, these powerful machines are crucial for completing construction and excavation projects efficiently. However, they require skilled operators to function safely and effectively. While modern excavators come equipped with advanced safety features, it’s still important to remember that operating one requires proper training and caution.

Â

Â

Operating heavy machinery always carries some level of risk. To ensure a safe working environment, here are 7 Essential Safety Tips that every excavator operator should follow:

Â

1. Inspect the Equipment Before Use

As an operator, it’s crucial to understand and inspect all key components of the excavator before starting work. Check the following:

- All safety devices (horns, lights, guards, fire extinguishers, wipers, etc.)

- Engine and hydraulic fluid levels

- Boom, stick, and bucket for damage or wear

- Control systems for proper function

Look for signs of leaks, loose bolts, or cracks in welds. Regular maintenance checks should be done on a monthly basis to ensure everything is in good working order.

Â

2. Maintain Responsibility and Awareness

Safety isn’t just about checking parts—it’s also about how you operate the machine. Keep the cab clean and free from obstructions. Clean the windshield regularly for better visibility. Always test controls before starting work and keep your seatbelt fastened. Avoid wearing slippery footwear and use the three-point method when entering or exiting the cab.

Â

3. Clear the Work Area

Before operating, make sure the site is clear of rocks, debris, and other hazards. Check for ditches, holes, and uneven ground. If working in a new area, contact local utilities to locate underground lines. Contact with power lines can be extremely dangerous and even fatal.

Â

4. Ensure Proper Fuel and Fluid Levels

Running out of fuel mid-operation can cause sudden shutdowns, which may lead to accidents. Always start with a full tank. Also, check engine and hydraulic fluid levels before beginning work. Low fluids can cause serious mechanical issues.

Â

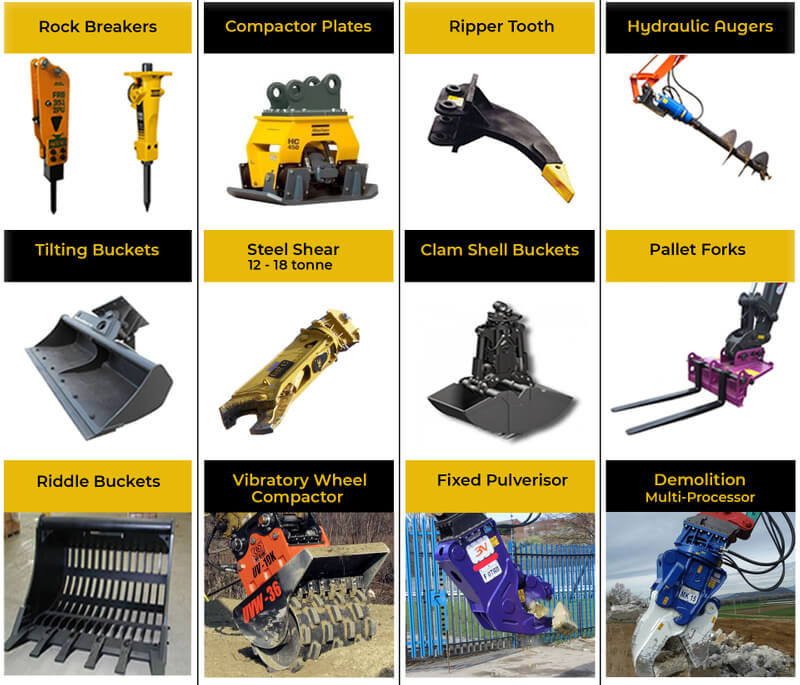

5. Use Approved Attachments

Only use manufacturer-approved attachments that match the job requirements. Heavy-duty buckets are ideal for various soil types, while severe-duty ones are suited for tough digging tasks. Never overload the bucket—always check the maximum capacity in the operator’s manual to avoid tipping or damage.

Â

6. Be Cautious on Slopes

Operating on uneven ground requires extra care. Never let the tracks run parallel to a slope, as this increases the risk of tipping. Move straight up slopes, keep the boom extended, and lower the bucket to maintain stability. Avoid sharp turns and sudden stops, especially in rough areas.

Â

7. Follow Best Safety Practices

Operators should never work when fatigued or under extreme weather conditions. Keep unauthorized personnel away from the machine and ensure everyone around is aware of its movements. Wear appropriate gear, including closed-toe shoes and protective equipment, and always face the machine when entering or exiting.

Â

These 7 tips are vital for maintaining a safe and efficient excavation process. By following them, you can significantly reduce the risk of injury, damage, and liability.

Â

RENT EXCAVATOR

At Antbuildz.com, we’re Singapore’s first digital equipment rental platform, designed to offer a seamless and touchless rental experience. Whether you need a Push Around, Boomlift, Generator, or Scissor Lift, you can search, compare prices, and rent instantly on our platform.

Visit antbuildz.com today and make your next project easier. Don’t forget to like and share our Facebook page at bit.ly/34MdSFh.

This category mainly includes Truck Tail Lift and Aluminium Tailgate.

Automobile Truck Tail Lift is also called automobile lifting Truck Tail Lift, automobile loading and unloading Truck Tail Lift, lifting Truck Tail Lift, and hydraulic automobile Truck Tail Lift. It is a hydraulic lifting and unloading device powered by on-board battery, which is installed at the rear of trucks and various vehicles. Automobile Truck Tail Lifts are widely used in aerospace, military, fire protection, postal, financial, petrochemical, commercial, food, medicine, environmental protection, logistics, manufacturing and other industries. It can greatly improve the transportation and handling efficiency, save costs, and is one of the modern logistics transportation equipment. Simply control the lifting and lowering of the Truck Tail Lift through the operation button, and the goods can be easily transferred between the ground and the car.The Truck Tail Lift has the characteristics of fast, safe and efficient, which can greatly improve the efficiency of transportation and handling. It is one of the modern logistics transportation equipment. It is widely used in logistics, post, tobacco, petrochemical, commerce, finance, manufacturing and other industries.

Tail Lift,Hydraulic Tail Lift,Hydraulic Truck Tail Lift,Hydraulic Car Lift

GUANGDONG NIULI LOGISTICS MACHINERY TECHNOLOGY CO.,LTD. , https://www.gdniulilogistics.com