Table of contents

- What is a 45-Degree Elbow?

- Benefits of Using 45-Degree Elbows in Construction and Infrastructure Projects

- Dimensions of 45-Degree Elbows

- Weight Chart for 45-Degree Street Elbows

- Materials and Grades for 3-Inch 45-Degree Elbows

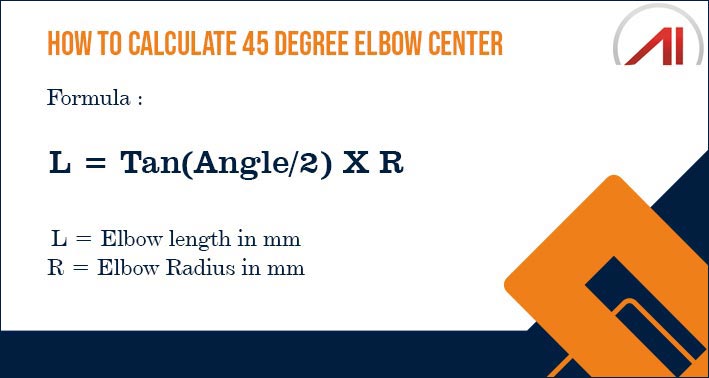

- How to Calculate the Center of a 45-Degree Elbow

- Pressure Rating of 45-Degree Elbows

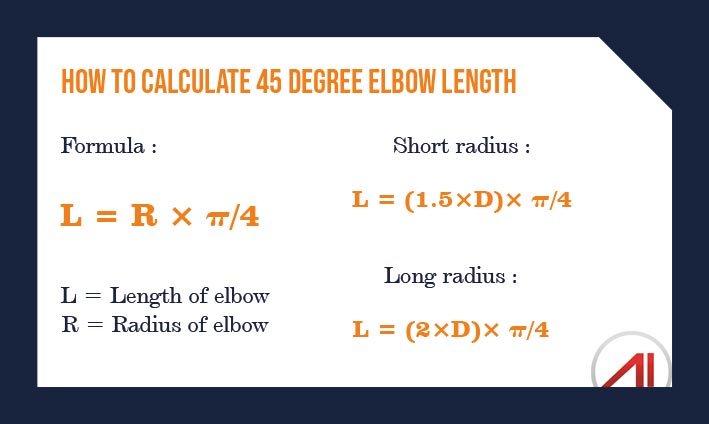

- Calculating the Length of a 45-Degree Elbow

- Features of 45-Degree Stainless Steel Elbows

- Disadvantages of 45-Degree Pipe Elbows

- Applications of 45-Degree Long Radius Pipe Elbows

What is a 45-Degree Elbow?

A 45-degree elbow is a type of pipe fitting used to change the direction of flow by 45 degrees. It helps maintain smooth fluid flow, reduce pressure loss, and prevent turbulence, which can affect the overall efficiency of the system.

Discover the Benefits of Using 45-Degree Elbows in Construction and Infrastructure Projects

Advantages of Using 45-Degree Elbows in Construction and Infrastructure Projects

- Versatility

- Easy Installation

- Improved Water Flow

- Cost-Effective

- Enhanced Aesthetics

- Increased Flow Efficiency

- Reduced Pressure Loss

- Smooth Fluid Flow

- Minimized Erosion

- Improved System Performance

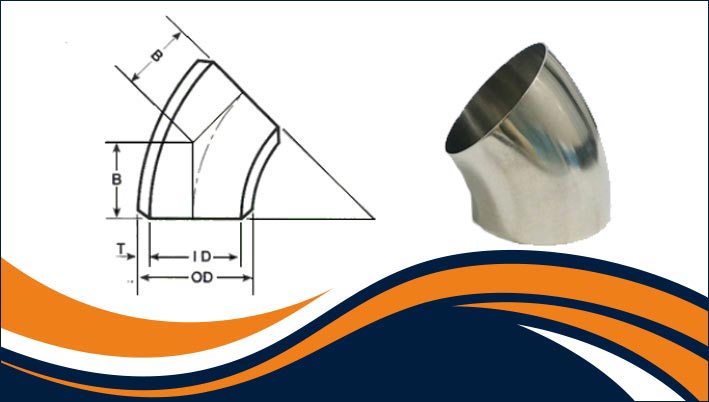

Understand the Sizes and Dimensions of 45-Degree Pipe Elbows

The size and dimensions of a 45-degree pipe elbow are crucial for ensuring a proper connection within the piping system. Matching the fitting size with the pipe diameter is essential to avoid leaks, structural damage, or inefficiencies in the system.

45-Degree Elbow Dimensions

| NPS | OD at Bevel | Center to End |

|---|---|---|

| 45 degree B | ||

| 1/2 | 21.3 | 15.7 |

| 1 | 33.4 | 22.4 |

| 1-1/2 | 48.3 | 28.4 |

| 2 | 60.3 | 35.1 |

| 3 | 88.9 | 50.8 |

| 4 | 114.3 | 63.5 |

| 6 | 168.3 | 95.2 |

| 10 | 273.1 | 158.8 |

| 14 | 355.6 | 222.2 |

| 18 | 457.2 | 285.8 |

| 22 | 558.8 | 342.9 |

| 26 | 660.4 | 406.4 |

| 30 | 762 | 469.9 |

| 34 | 863.6 | 533.4 |

| 38 | 965.2 | 599.9 |

| 42 | 1066.8 | 660.4 |

| 46 | 1168.4 | 726.9 |

| 52 | 1320.8 | – |

| 56 | 1422.4 | 883.8 |

| 66 | 1676.4 | 1041.6 |

| 72 | 1829 | 1137 |

| 80 | 2032 | 1263 |

Check the Weight Chart for 45-Degree Long Radius Pipe Elbows

Knowing the weight of a 45-degree long radius elbow is important for safe handling and installation. The weight also plays a role in determining the cost of the fitting for the entire piping system.

45-Degree Street Elbow Weight Chart

| NPS in inch | Sched XXS in kilogram |

Sched 160 in kilogram |

Sched XS in kilogram |

Sched STD in kilogram |

|---|---|---|---|---|

| 1/2 | Â | Â | Â | .04 |

| 3/4 | .08 | Â | .07 | .04 |

| 1 | .18 | .17 | .13 | .11 |

| 1 1/4 | .25 | .23 | .20 | .15 |

| 1 1/2 | .52 | .35 | .27 | .21 |

| 2 | .96 | .79 | .47 | .35 |

| 2 1/2 | 1.7 | 1.35 | .86 | .75 |

| 3 | 2.6 | 2.0 | 1.39 | 1.01 |

| 3 1/2 | 3.9 | Â | 2.14 | 1.42 |

| 4 | 4.8 | 4.3 | 2.65 | 1.91 |

| 5 | 8.6 | 7.65 | 4.65 | 3.26 |

| 6 | 14.4 | 13.5 | 7.5 | 5.18 |

| 8 | 27 | 29 | 15 | 10 |

| 10 | Â | 61 | 24 | 18 |

| 12 | Â | 104 | 33 | 27 |

| 14 | Â | 125 | 43 | 33 |

| 16 | Â | 187 | 59 | 46 |

| 18 | Â | Â | 77 | 57 |

| 20 | Â | Â | 92 | 70 |

| 24 | Â | Â | 133 | 100 |

| 26 | Â | Â | 164 | 124 |

| 30 | Â | Â | 214 | 165 |

| 36 | Â | Â | 318 | 239 |

| 42 | Â | Â | 428 | 320 |

45-Degree Elbows Are Available in Various Materials, Including Stainless Steel, Carbon Steel, and Nickel Alloys

Each material has unique properties that make it suitable for different applications. Below is a list of materials, standards, and grades commonly used for 45-degree elbows, which can help you choose the right one for your project.

3-Inch 45-Degree Elbow Materials and Grades

| Material | Standards and Grade |

|---|---|

| Carbon Steel |

|

| Incoloy |

|

| 45-Degree Stainless Steel Elbow |

|

| Copper Nickel 45-Degree Angle Elbow |

|

| Alloy Steel 45-Degree Pipe Elbow |

|

| Titanium 45-Degree Black Elbow |

|

| Inconel 45-Degree Long Radius Pipe Elbow |

|

| Hastelloy 45-Degree LR Pipe Elbow |

|

| Super Duplex |

|

| Nickel Alloy |

|

| 45-Degree Aluminum Elbow |

|

| Duplex |

|

Calculate the Center of a 45-Degree Elbow

45-Degree Angle Elbow Pressure Rating

| Temperature | Class (lbs) | ||||

|---|---|---|---|---|---|

| 150 | 300 | ||||

| oC | oF | 2 1/2 – 3 inch. | 1 1/4 – 2 inch. | 1/4 – 1 inch. | |

| -29 to 66 | -20 to 150 | 300 | 1000 | 1500 | 2000 |

| 93 | 200 | 265 | 910 | 1350 | 1785 |

| 121 | 250 | 225 | 825 | 1200 | 1575 |

| 149 | 300 | 185 | 735 | 1050 | 1360 |

| 177 | 350 | 150 | 650 | 900 | 1150 |

| 204 | 400 | – | 560 | 750 | 935 |

| 232 | 450 | – | 475 | 600 | 725 |

| 260 | 500 | – | 385 | 450 | 510 |

| 288 | 550 | – | 300 | 300 | 300 |

How to Calculate the Length of a 45-Degree Elbow

45-Degree Black Elbows Are Manufactured According to ASME B16.9 Standards

ASME B16.9 is an industrial standard for butt-weld fittings, established by the American Society of Mechanical Engineers. It covers aspects such as sizes, tolerances, pressure ratings, materials, surface finish, and testing requirements for these fittings.

Features of 45-Degree Stainless Steel Elbows

- Smooth Interior Surface

- Resistant to Mechanical Stress and High Pressure

- Durable and Long-Lasting

- Excellent Performance

- Easy to Install

- High Temperature Resistance

Disadvantages of 45-Degree Pipe Elbows

- Pressure Loss

- Flow Disruption

- Requires More Space

- More Expensive Than Straight Sections

- Needs Regular Maintenance

- Limited for Sharp Turns

- Increases Friction

Applications of 45-Degree Long Radius Pipe Elbows

- Water Supply Systems

- Chemical Industry Pipelines

- Food Processing Pipelines

- Air Conditioning Systems

- Electronics Manufacturing

- Solar Energy Systems

- Agricultural Irrigation

- Heating, Ventilation, and Air Conditioning (HVAC) Systems

- Drainage Systems

- Gas Distribution Lines

multi-component injection molding,multi- material mold,multi-material plastic mould,multi material injection molding

Dongguan Hongke Plastic Precision Mould Co.,Limited , https://www.hongkemold.com